The stretching system, the blowing nozzles, the lubricating system, and the cooling water circualting.

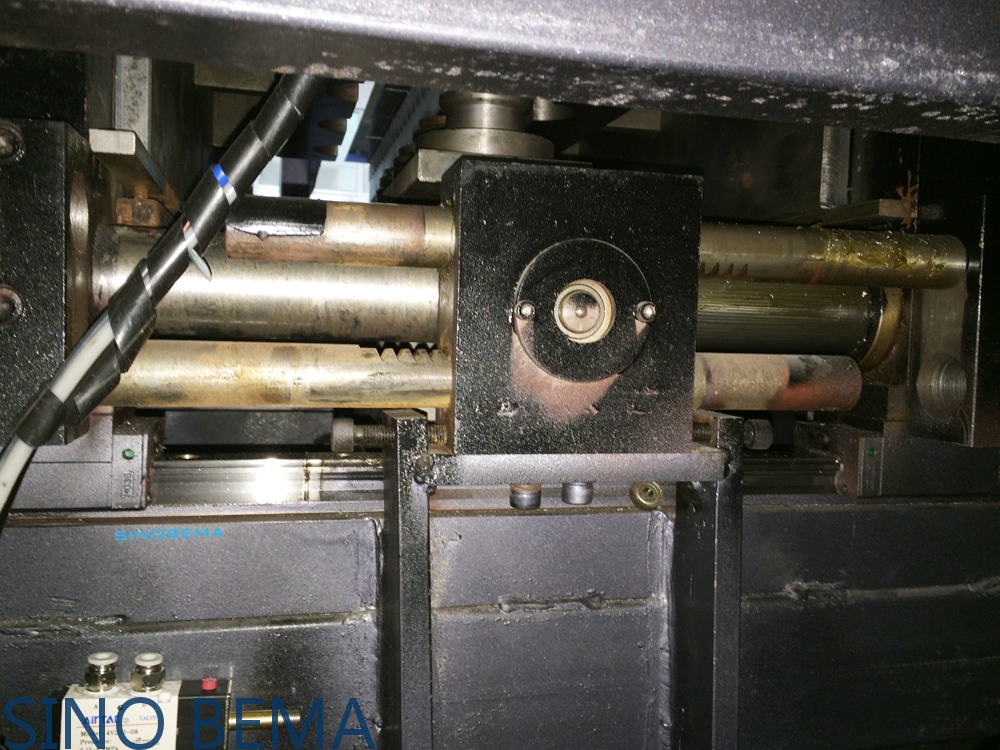

A. The stretching system.

The stretching cylinder lifts the stretching slider, which keep the stretching system on the rail, and in right working position.

1. The distance between the stretching cylinder and the rolling wheel should be checked every month, to make sure there are 0.1-0.2mm distance, then the rail will not be damaged easily.

2. Check regularly if the screws and bolts are fixed tight on the stretching cylinder.

3. Check regularly if the the solenoid and air tubes are leaking air.

B. The blowing nozzles and the seals

The small compensation holes on the blowing nozzles are used for making sure the pressure in & external the screws are the same.

The blowing nozzles should be checked regularly, and the damaged or worn out seals should be replaced.

C. Cooling water circulating.

The flow quantity of the cooling water should be checked regularly to make sure it can provide enough cooling water to the molds.

The filter and water tank inside the chiller machine should be check every month too.

D. Air supplying system

This system is working for handling and distributing the high pressure air

The air pressure indicator on the control panels should be checked often to see if the pressure is right.

The water inside the oil filter should be drained every week.

E. Lubricating system

The external parts of the lubricating system should be cleaned often.

The lubricating oil quantity should be checked every day to make sure there are enough lubricating oil or butter there.

All necessary parts should be lubricated regularly.

- HOME

- US & NEWS

- PRODUCTS

- Water treatment machinery

- Auxiliary Equipment

- Sea water to pure water

- Household RO filter

- Normal (tap/well/river/lake) water to pure drinking water

- 1000 liters per hour RO/water treatment/purification system

- 2000 liters per hour RO/water treatment/purification system

- 3000 liters per hour RO/water treatment/purification system

- 5000 liters per hour RO/water treatment/purification system

- 8000 liters per hour RO/water treatment/purification system

- 10000 liters per hour RO/water treatment/purification system

- Distillery euipments, to make Whiskey and fruit wine

- Bottle blow molding machinery

- 1 cavity, semi auto Wide-neck PET cans/cup/bottle blow molding machine

- Full auto bottle blow molding machinery

- 2 cavity semi-auto blow molding machine, 200ml to 2000ml

- 5gallon/19.8L bottle/barrel blow molding machine

- PC bottle blow moulding machine

- 5gallon PET water bottle full auto blow moulding machine

- Full automatic bottle blow molding machinery

- 4 cavity semi auto bottle blow molding machinery

- 5 liter, 1 cavity semi-auto blow molding machine, 200ml to 5000ml

- 2+2 cavity semi-auto blow molding machine, 200ml to 2000ml

- Full automatic blow molding machine for 5 liter PET water bottles

- 2 cavity semi-auto blow molding machine, 4/5/6/7 liter

- 1 cavity, full auto Wide-neck PET cans/cup/bottle blow molding machine

- 2 cavity, full auto Wide-neck PET cans/cup/bottle blow molding machine

- PET plastic wine bottles blow molding machine

- 0.2-5 liter, HDPE bottles molding machine

- Washing, filling& capping machinery

- 100-2000ml bottles washing, filling capping machinery(3-in-1)

- 5gallon/18.9-liter, 100BPH washer filler capper machine

- 4 nozzles filler machine for small water bottles

- 5gallon/18.9-liter, 200BPH washer filler capper machine

- 5gallon/18.9-liter, 300BPH washer filler capper machine

- 5gallon/18.9-liter, 400BPH washer filler capper machine

- 5gallon/18.9-liter, 600BPH washer filler capper machine

- 5gallon/18.9-liter, 900BPH washer filler capper machine

- Wine bottle filling machine, wine filler

- 5-liter water bottle washer, filler, capper machine

- Capping/sealing machine for aluminum caps, full automatic model

- Capping/sealing machine for aluminum caps, semi automatic model

- 100-2000ml bottles washing, filling capping machinery(Linear model)

- 3-11L bottle washing filling capping machinery

- 5-liter water bottle washing filling capping machine (3-in-1 model)

- Semi-automatic bottling line for 18.9-liter bottles

- 3-5gallon bottle washing filling capping machinery

- De-capper machine

- Bottles in&external brush wash machine

- Auto bottle loading system

- Light check system

- Empty bottles and full bottled conveyor systems

- Neck label shrink machine

- Pre washer for 5 gallon water bottles

- Bottle labeling machinery

- Single side labeling machine for adhesive sticker labels

- Flexographic printing machine, adhesive stickers printing machine

- Wine bottle labeling machine, front label and back label

- Double sides labeling machine for adhesive sticker labels

- Flexographic printing machine, adhesive stickers printing machine

- Wowen/non-wowen bags, flour bags printing machine, Maize miller bags

- Hot glue labeling machine

- Single nozzle sleeve labeling machine

- Double nozzle sleeve labeling machine

- Bottle coding system

- Bottle packing systems

- Semi auto shrinkable PE film packing machine

- Liquid packing machine

- "L" model shrinkable PE film packing machine

- Full automatic carton packing machine

- Linear model shrinkable PE film packing machine

- Semi automatic carton packing machine

- Linear model shrinkable PE film packing machine, double tunnels model

- Paper cups molding machine

- Injection molding machine

- Turnkey bottling plants solutions

- Lighting Equipments

- AUTOMOTIVE REPLACEMENTS AND ACCESSORIES

- Consumables and accessories

- 55mm neck PET preforms

- 28/30mm neck PET preforms

- 55 mm neck caps

- 28/30mm neck caps

- PE plastic film

- OPP labels

- PVC shrinkable labels

- Adhesive stickers labels

- Bottle blow mold

- UHT treatment

- Steam generator

- Preforms injection mold

- Shrink tunnel

- Air compressors and air tank

- Water chiller

- PP caps slitter machine

- Air cold dryer

- Bottle caps loading system

- Bottle air blow dryer

- RO (reverse osmosis ) membrane

- Water dispenser

- Sourcing Service

- Water treatment machinery

- TECH & INFO

- CONTACT US

- VIDEOS STUDIO

- HOME

- US & NEWS

- PRODUCTS

- Water treatment machinery

- Auxiliary Equipment

- Sea water to pure water

- Household RO filter

- Normal (tap/well/river/lake) water to pure drinking water

- 1000 liters per hour RO/water treatment/purification system

- 2000 liters per hour RO/water treatment/purification system

- 3000 liters per hour RO/water treatment/purification system

- 5000 liters per hour RO/water treatment/purification system

- 8000 liters per hour RO/water treatment/purification system

- 10000 liters per hour RO/water treatment/purification system

- Distillery euipments, to make Whiskey and fruit wine

- Bottle blow molding machinery

- 1 cavity, semi auto Wide-neck PET cans/cup/bottle blow molding machine

- Full auto bottle blow molding machinery

- 2 cavity semi-auto blow molding machine, 200ml to 2000ml

- 5gallon/19.8L bottle/barrel blow molding machine

- PC bottle blow moulding machine

- 5gallon PET water bottle full auto blow moulding machine

- Full automatic bottle blow molding machinery

- 4 cavity semi auto bottle blow molding machinery

- 5 liter, 1 cavity semi-auto blow molding machine, 200ml to 5000ml

- 2+2 cavity semi-auto blow molding machine, 200ml to 2000ml

- Full automatic blow molding machine for 5 liter PET water bottles

- 2 cavity semi-auto blow molding machine, 4/5/6/7 liter

- 1 cavity, full auto Wide-neck PET cans/cup/bottle blow molding machine

- 2 cavity, full auto Wide-neck PET cans/cup/bottle blow molding machine

- PET plastic wine bottles blow molding machine

- 0.2-5 liter, HDPE bottles molding machine

- Washing, filling& capping machinery

- 100-2000ml bottles washing, filling capping machinery(3-in-1)

- 5gallon/18.9-liter, 100BPH washer filler capper machine

- 4 nozzles filler machine for small water bottles

- 5gallon/18.9-liter, 200BPH washer filler capper machine

- 5gallon/18.9-liter, 300BPH washer filler capper machine

- 5gallon/18.9-liter, 400BPH washer filler capper machine

- 5gallon/18.9-liter, 600BPH washer filler capper machine

- 5gallon/18.9-liter, 900BPH washer filler capper machine

- Wine bottle filling machine, wine filler

- 5-liter water bottle washer, filler, capper machine

- Capping/sealing machine for aluminum caps, full automatic model

- Capping/sealing machine for aluminum caps, semi automatic model

- 100-2000ml bottles washing, filling capping machinery(Linear model)

- 3-11L bottle washing filling capping machinery

- 5-liter water bottle washing filling capping machine (3-in-1 model)

- Semi-automatic bottling line for 18.9-liter bottles

- 3-5gallon bottle washing filling capping machinery

- De-capper machine

- Bottles in&external brush wash machine

- Auto bottle loading system

- Light check system

- Empty bottles and full bottled conveyor systems

- Neck label shrink machine

- Pre washer for 5 gallon water bottles

- Bottle labeling machinery

- Single side labeling machine for adhesive sticker labels

- Flexographic printing machine, adhesive stickers printing machine

- Wine bottle labeling machine, front label and back label

- Double sides labeling machine for adhesive sticker labels

- Flexographic printing machine, adhesive stickers printing machine

- Wowen/non-wowen bags, flour bags printing machine, Maize miller bags

- Hot glue labeling machine

- Single nozzle sleeve labeling machine

- Double nozzle sleeve labeling machine

- Bottle coding system

- Bottle packing systems

- Semi auto shrinkable PE film packing machine

- Liquid packing machine

- "L" model shrinkable PE film packing machine

- Full automatic carton packing machine

- Linear model shrinkable PE film packing machine

- Semi automatic carton packing machine

- Linear model shrinkable PE film packing machine, double tunnels model

- Paper cups molding machine

- Injection molding machine

- Turnkey bottling plants solutions

- Lighting Equipments

- AUTOMOTIVE REPLACEMENTS AND ACCESSORIES

- Consumables and accessories

- 55mm neck PET preforms

- 28/30mm neck PET preforms

- 55 mm neck caps

- 28/30mm neck caps

- PE plastic film

- OPP labels

- PVC shrinkable labels

- Adhesive stickers labels

- Bottle blow mold

- UHT treatment

- Steam generator

- Preforms injection mold

- Shrink tunnel

- Air compressors and air tank

- Water chiller

- PP caps slitter machine

- Air cold dryer

- Bottle caps loading system

- Bottle air blow dryer

- RO (reverse osmosis ) membrane

- Water dispenser

- Sourcing Service

- Water treatment machinery

- TECH & INFO

- CONTACT US

- VIDEOS STUDIO

Copyright © 2017-2099

Chengdu Sino Beverage Machinery Co., Ltd. All Rights Reserved

Web visiting with 1024*768 resolution is strongly recommended

Site links: Sinobema China Ministry of Commerce CCPIT 施诺机械设备有限公司(中国)